4 to mt 12 Dimensions mm 570 from mt 6 to mt 14xh. DESIGN OF COOLING TOWER B Bhavani Sai.

Chocolate Cooling Tunnel 300 400 500 Chocolate Machine Selmi Group

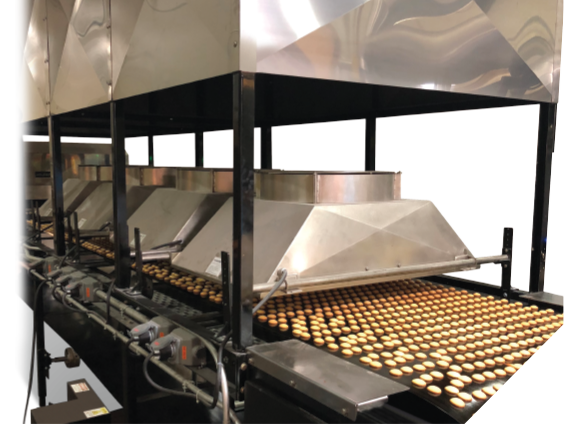

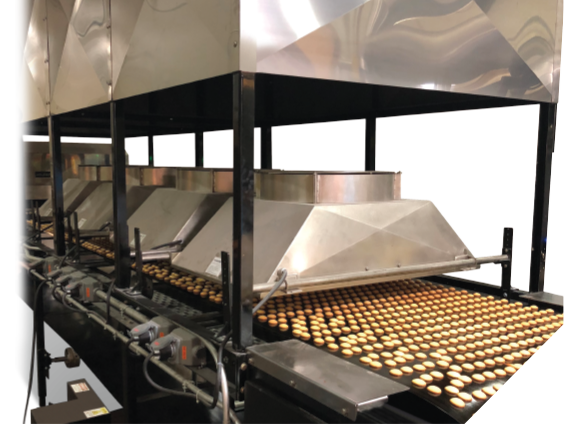

Experience and know-how combined with our latest scientific research have resulted in the current cooling tunnel design to improve cooling efficiency and product quality.

. A one-eighth inch crack that runs 100 feet is the same as a one square foot hole in the wall. Multiple cooling module arrangements are available to handle a wide variety of cooling requirements. Pre-support ground treatment temporary invert.

Designed inlets tunnel air velocity drops and wind-chill cooling is reduced. What might seem to be insignificant cracks or gaps say along an uncaulked sidewall sill plate can quickly add up. The whole machine is beautiful and easy full consideration of GMP hygiene requirements.

Stainless steel convers body design convenient to. It was found that 14-1645 Kw of refrigeration capacity per ton of table grapes is an optimum approach for the designing of forced-air cooling system. Continuous cooling tunnels are designed for applications in which all products require the same cool down period.

4681012 USEFUL - BELT WIDTH 180250320 mm. Cooling with ring air ventilation Refrigerating unit with air cooling system. The cooling tunnels are designed with a focus on simple and clean design and due to remarkable flexible airflow the result is an environmentally friendly and.

The ubiquitous element 37 21 The nature of design and its application to tunnelling 37 211 Characteristics of design 38 212 The parties to the design process 39 213 Uncertainty and risk 40 214 Qualifications for the design team 47 22 Steps in the design process 48 23 Examples of application of the principles 54. Such as the chocolatecandybiscuit Wafer etc. 00714 Lbft3 Air Specific Volume.

Tunnel design shall follow the above dimensions and clearance in height for the traffic is determined as 50m which is the standard for Asian Highways. Tunnel Support Design Summary Summary Project-specific ground characterization Compatible excavation methodology Hard rock tunnel. By contrast discontinuous cooling tunnels are designed for applications in which products need to exit from the tunnel as soon as a desired end.

Further if we really need maximum cooling and have. 2 K S L Prasanna. 463774 BtuLb dry air Download the example file exe1_1zip This file covers the examples of 1-1 through 1-4.

PLC and precision sensors regulate the air temperature within the tunnel. The design of cooling tower is based on the following parameter Mass flow rate 10 LPM 10 60 LPH Mass flow rate 600 LPH Mass flow rate 1667 10 -4 m3 sec Mass flow rate 1667 10-4 1000 Mass flow rate 01667 Kgsec Where 1 m3sec 1000 Kg sec Surrounding condition 5 WBT 28º C. The technical data has been taken from a mechanical draft cooling tower.

The close-fitting PU covers give an airtight seal without any sealing material. Those interested in the subject of tunnel design should also consult published reports of other ITA working groups eg. INTRODUCTION TO OLD AND NEW ERA.

Continuous face and periphery support GW control monitoring Contingency Risk Mitigation measures. Material on either side of the tunnel. 3 K Srinivasa Rao.

143309 ft3Lb dry air Air Enthalpy. Cooling Tower Thermal Design Manual Air Density. Erik Eberhardt qu y upp which is equivalent to a height Hp.

The cooling tunnels are of modular design and consist of individual 3 m long sections. All the drive parts meet GMP hygiene requirements totally. This special process together with the curves one-piece and close-fitting design eliminates cold bridges.

Rock mass discontinuities strength and abrasion Soft-ground tunnel. 1270 Volt 400 Hz 50 Kw 24 three-phase 5 poles special voltages on request Optional. Standard modules provide up to 6 tons 18000 Kcalhr of cooling while free-standing condensers provide the capacity needed for larger cooling loads.

Terzaghi related this parameter to the tunnel dimensions and characteristics of the rock mass to define a series of steel arch. Cover Nielsen cooling tunnel covers are unique in both design and materials. With its various available sizes our Perfect Cooling Tunnel is made for increasing productivity with a quick and constant cooling of the chocolate coatings.

Lead- and freon-free insulation material with highly consistent and stable physical properties is sandwiched between and bonded to aluminum plates. There are two basic types of cooling tunnels. AMC cooling tunnel is mainly used for cooling food industry.

The recent ITA report on contractual sharing of risk see TUST 32 and ITA recommendations on maintenance of tunnels see TUST 23. Design and Operation Considerations 2012 Instructor. 932 Rock classification method and Standard Support Patterns of the tunnel 1 Rock classification system and standard support patterns in Japan.

The easy to clean design permits for quick clean-up. 72 molds Verticale 275. ChE PDH Online PDH Center 5272 Meadow Estates Drive Fairfax VA 22030-6658 Phone Fax.

Issues opportunities and Challenges for Development ISBN. The course also includes the selection and installation of various tunnel lining methods the selection and construction of various shafts for tunneling and key aspects of tunnel design specification cost and construction management with particular emphasis on risk management and mitigation during the design and construction process. COOLING TUNNEL FEATURES Modular design consisting of a 4 foot infeed section 8 foot cooling sections and a 4 foot discharge section.

Each section can be individually controlled for temperature zoning to prevent moisture and condensation. As such the roof and sides of the tunnel are required only to support the balance 4 of 34 Tunnelling Grad Class 2012 Dr. Abstract This paper presents detailed methodology of a Induced draft cooling tower of counter flow type in which its efficiency effectiveness char-acteristics are calculated.

TUNNELS AND TUNNELING OPERATIONS. Cooling with ring air ventilation Refrigerating unit with air cooling system Height passing product mm 130290 Belt width mm 180250320 Refrigerating length from mt. Conveyor speed 12 FPM Length of the tunnel 52 FT.

The unique design allows the installation in open laboratories.

Industrial Cooling Tunnel Manufacturers Advantech

Pdf Pre Cooling Systems For Small Scale Producers

Pdf Wind Catcher Earth Air Tunnel A Tool For Passive Cooling For Residential Home In New Cites Of Egypt The Fourth Annual Asian Conference On Sustainability

Forced Air Cooling Systems For Fresh Ontario Fruits And Vegetables

Tunnel 600 Mm Chocolate Coating And Cooling Tunnel Selmi Group

Pdf Design Aspects In The Precooling Process Of Fresh Produce

Pdf Greenhouse Design And Cooling Technologies For Sustainable Food Cultivation In Hot Climates Review Of Current Practice And Future Status

Candy Making Equipment Candy Baking Equipment And Confectionery Supplies By Savage Bros

0 comments

Post a Comment